ew generation of chemical extractor hoods ASEM® DPC2.

Unique V.A.V. system with certified response time of 0.5 seconds. With V.A.V. (RMP) and double suction with double motor as required by Standard UNI/TS 11710 – May 2018.

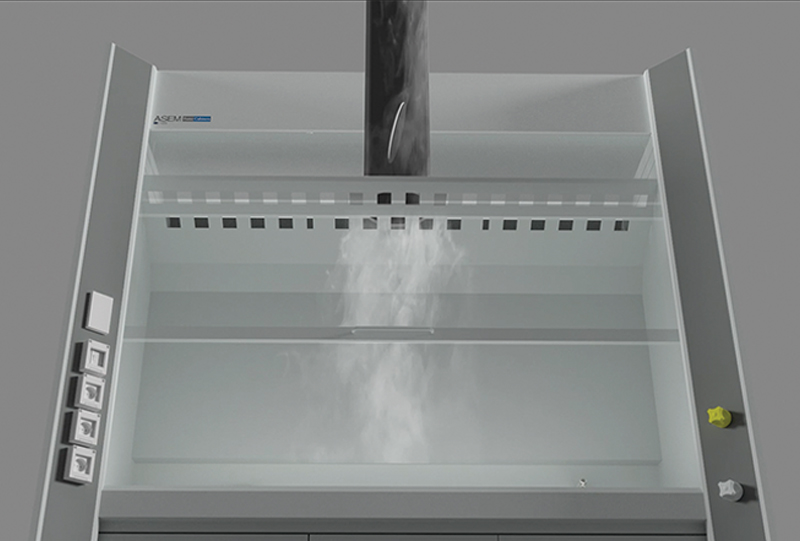

Total extraction Chemical Hoods are normally provided with a “double intake” obtained from a rear panel that, connected to the celine, increases the speed in its “cavity” favoring the extraction of heavy vapors stagnant on the work surface.

The patented DPC2 system consists of an aspiration in the lower part, and eventually on the sides of a fully extracting Chemical Hood, mechanical carried out by a remote fan motor.

This suction will act in conjunction with the main suction, is adjustable manually or automatically via frequency variator.

With the glass raised it will give preference and air flow rate in greater extraction to the main engine. With the glass lowered it will give preference and extraction capacity to the lower engine.

The advantages of the double-suction system are a reduction in the flow rates normally required, a homogeneous suction that avoids turbulence, the possibility of increasing or decreasing the suction rates depending on the needs of the operator and the type of product handled.

New generation of chemical extractor hoods ASEM® DPC2.

The RMP system can be adjusted for the speeds required by the operator, even in a second time in a few seconds, to have suction rates from 0.3 to 0.7 m/s. No risk of remaining in “cream” with the RMP system, the maintenance and/or control will be carried out in conjunction with the ordinary maintenance of the hood. The valve, even in the absence of electricity, will remain open still ensuring a slight suction for “chimney effect”.

The RMP system, having no electrical components, can be installed in ATEX zones combined with a flow alarm system with “cross measurement”.

The device, patented MO2012A000139, allows you to adjust the airflow rate of a Chemical Hood with total expulsion while maintaining constant intake rate.

The adjustment is via a butterfly valve that opens and closes automatically in a linear way when the glass is raised or lowered up and down.

The system is automatically unlocked in case it is necessary to open more than 40 cm to do maintenance or let an instrument enter the intake chamber.

The advantage of this system compared to the motorized system and the frequency variator, in addition to economy, is the immediate response without “dead” times and inertia.